For every production line

The range of our mixing systems includes:

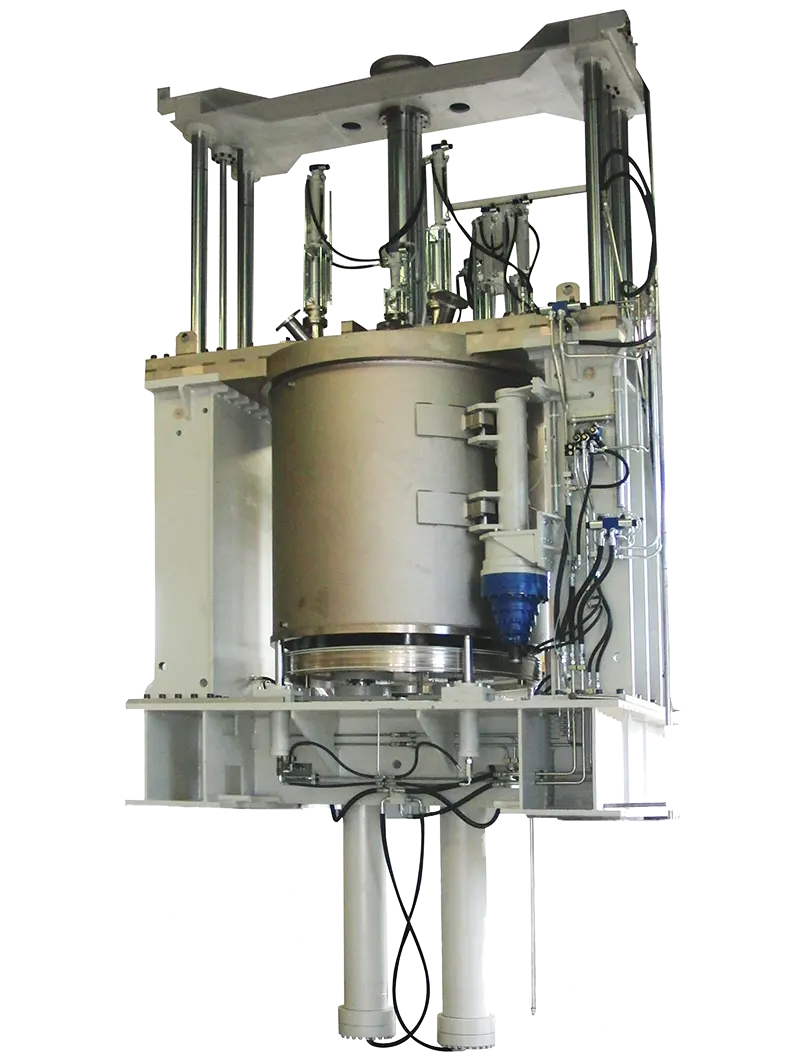

• sigma mixers for pastes with high viscosity (TKE)

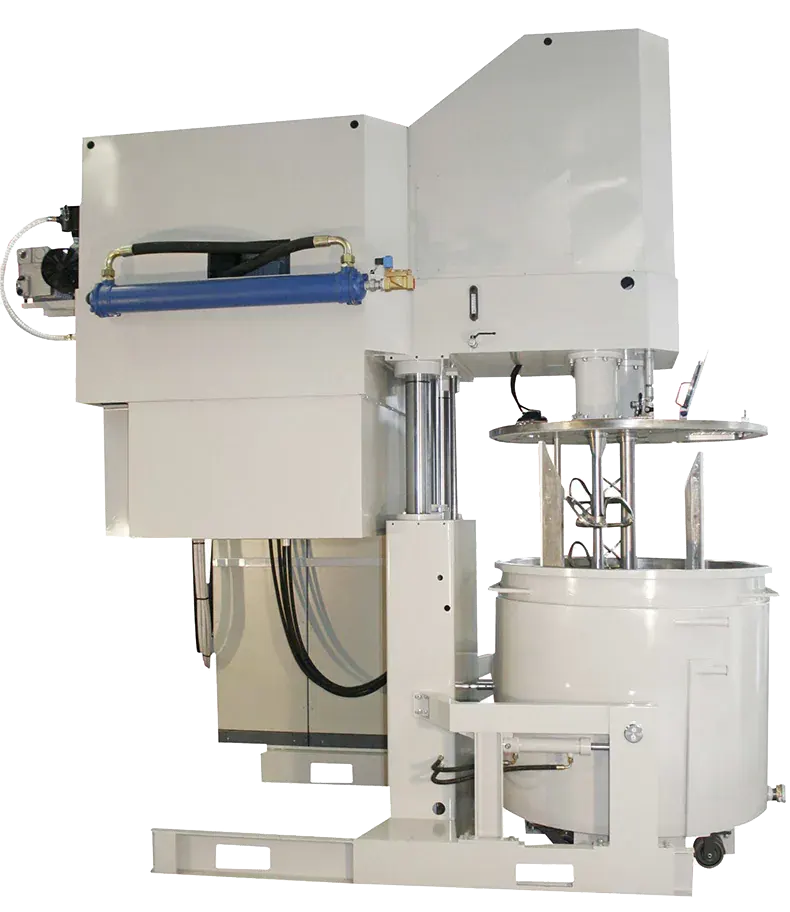

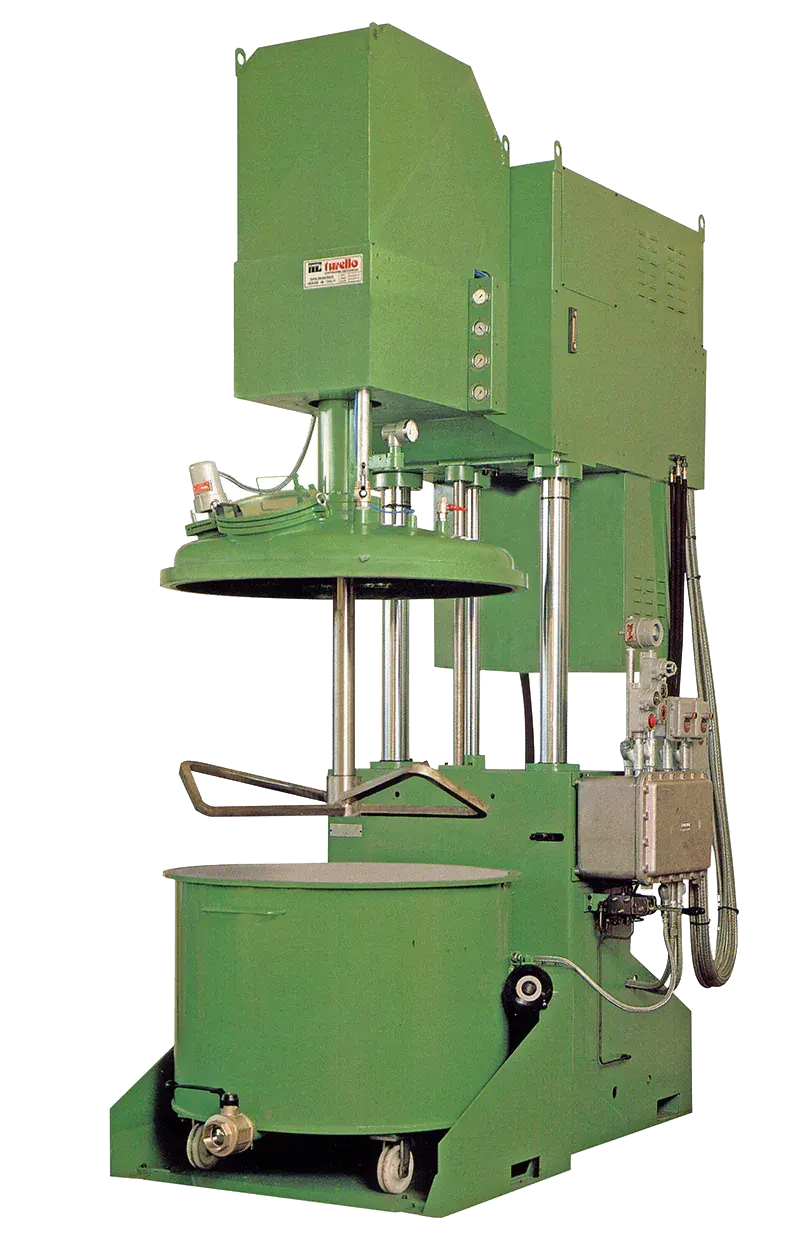

• planetary mixers (TMDLPS)

• mixers with three shafts and mobile head (TMD) or with fixed head (TMS)

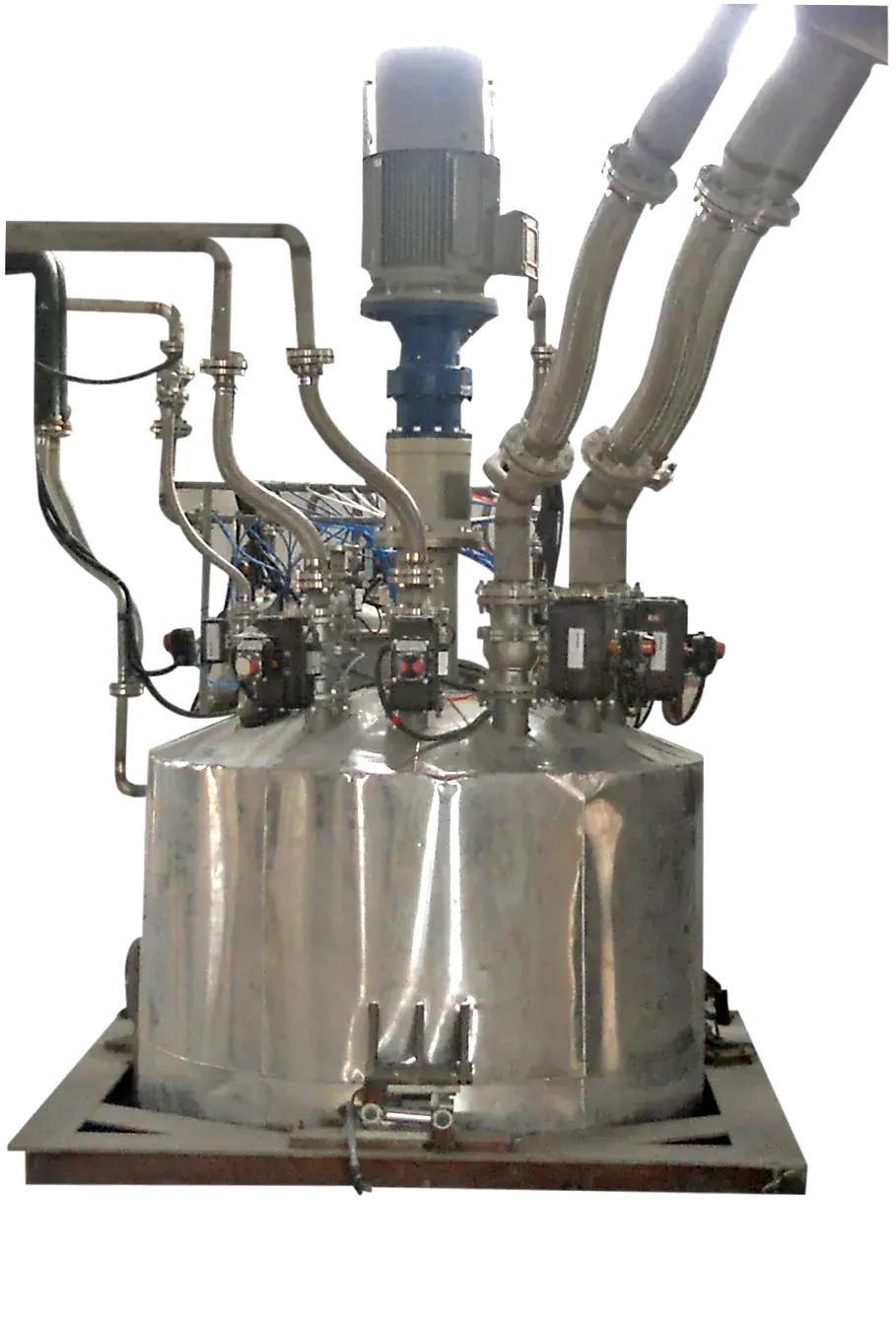

• butterfly mixers (TBM)

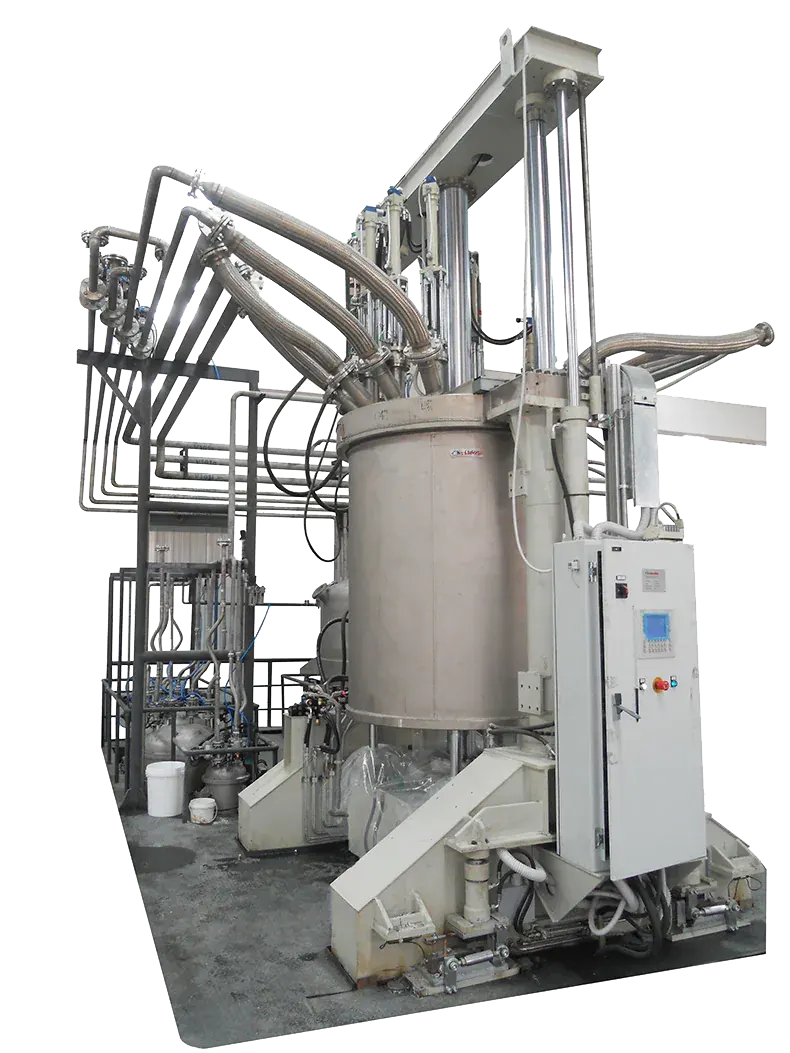

• through-floor mixers (TMR)

• dispersers (TDH).

Our continuous research has enabled us to develop specific mixers for some types of product:

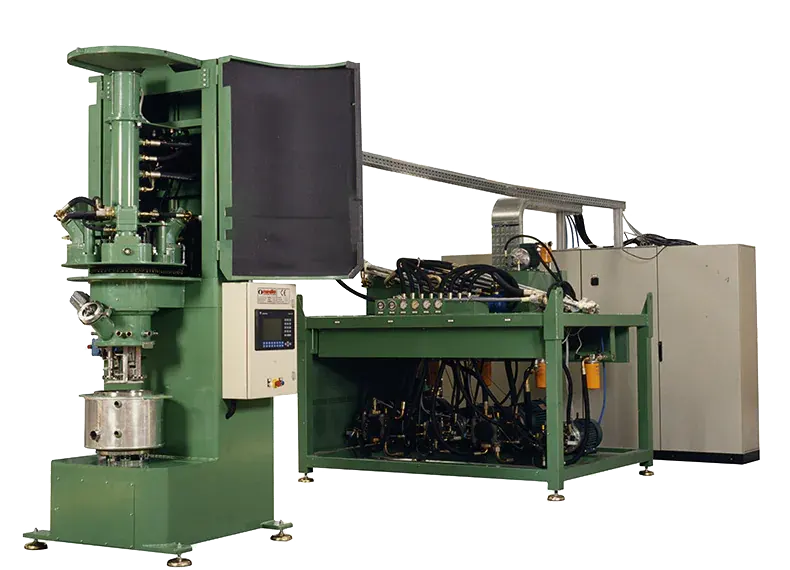

• TMDLP planetary mixers for the production of LSR

• TMBS butterfly mixers for the production of polyurethane sealants

• TPM pressmixers for the sealants production in continuous line

• TMX mixers for the preparation of the liquid components in sealants production lines

For over 30 years our company has developed in line pigmentation systems for sealants with medium and high viscosities.

Particularly appreciated for :

• the flexibility in the production process and suitable for the production of small batches,

• the elimination of inventories

• the reduction of cleaning time, both in mixing and extrusion systems.

They can be supplied either in fully automatic version (DSM) for the most applications or in semi-automatic version (DSMM) for less accurate applications.

Being able to reproduce the exact development of the production process on a reduced scale is a necessary demand for the research and development of new products.

The two series of mixers from our production, (TLM) and (TLMLP), ensure perfect reproducibility of the industrial process and are valid solutions to this need.

Filling

Filling Mixing

Mixing Dosing

Dosing Extrusion

Extrusion Cleaning

Cleaning Packaging

Packaging Storage & movement

Storage & movement Plants

Plants Accessories

Accessories